Cooling and Drying Equipment

-

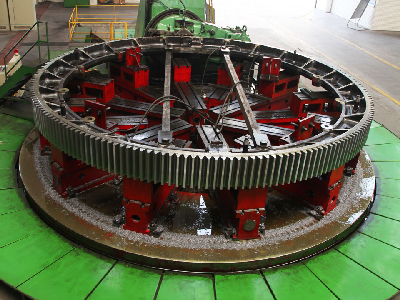

- Monocular Cooler

It enables the clinker, the temperature of which is 1000℃ to 1200℃, coming from the rotary kiln to fully exchange with the air through the rotation of the shell body, making the material cool down to 200℃ or lower while improving the grindability of the material. Feed the air used to cool the clinker into the kiln for secondary circulation, which can improve the thermal efficiency of the kiln.

-

- Rotary Dryer

Under the action of these lifting blades, the hydrous materials spread in the rotating body. Water inside the materials is turned into vapor by the hot air and then the vapor is released into the atmosphere, so the materials are dried. The rotary dryer is used for the drying of slag, clay, limestone, and other materials. It is mostly applied in the industries of cement, chemical, metallurgy, building ...

-

- Double Drum Rotary Dryer

Materials exchange heat with the hot air in the form of radiation, convection or conduction in the inner drum, while in the outer drum, heat exchange is performed through both conduction and convection. The lifting blades of multiple designs make the materials exchange heat with the hot air more fully.

-

- Triple Pass DryerThe length of the triple drum rotary drying machine is only 40% of that of the single drum product, which is conducive to process layout. This also reduces plant construction area and saves 40% of the project investment. The floor area of this triple pass dryer is approximately 20 square meters.

Jiangsu Pengfei Group Co., Ltd. is a leading manufacturer of rotary kilns and grinding equipment, and in 2019, we were successfully listed on the Hong Kong stock exchange, demonstrating our close relationships with our customers. At Pengfei, we offer design, production and services for construction, metallurgy, chemical and environmental protection industry. As an EPC service provider, we provide customized one-stop solutions including design, procurement, construction and trial operations to better serve our clients.