- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

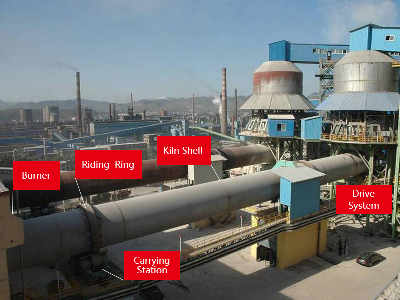

Rotary Kilns

Pengfei Group is a leading manufacturer of precision engineered rotary kilns (also called as rotary calciners and rotary furnaces), offering you custom-tailored rotary kiln solutions. Known for durability, reliability and functionality, our rotary kiln systems are widely used in the metal and cement industry. With extensive experience in thermal processing applications, we are capable of engineering, designing and manufacturing rotary kilns to meet the specific needs of the project at hand. If you are looking for sturdy, tested and safe rotary kilns, looking no further than Pengfei Group.

The basic components of a rotary kiln includes: end seal, riding ring, kiln shell, burner, carrying station, drive system

The rotary kiln, a rotary cylindrical vessel driven by gear, is used to raise materials to a high temperature in a continuous process. It can not only satisfy the heat exchange requirements in various stages of clinker formation but also meet the requirements of heat, temperature, time and physical and chemical reactions for different mineral formation.

The rotary kiln consists of refractory bricks, cast refractory concrete and shell made from special steel plate. The rotary kiln is widely used in building material, metallurgy, chemical and environmental protection industry for calcining cement, active lime, calcium carbonate, titanium dioxide, magnesium oxide, zinc oxide etc., oxidizing roasting nickel, iron, lithium, chromium and non-ferrous mineral, smelting gold and copper, oil making from coal, cleaning and dry distillation of coal, oil extraction from oil sand and oil shale, disposal of solid waste, hazardous waste and etc.

- Decades of experience with rotary kilns for material development and production

- Large scale production facilities for rotary kilns

- A variety of rotary kiln options available to adapt to all types of applications

- Modular kiln design makes it adaptable to the specific needs of the project

- Convenient monitoring of the project and continuous quality control can be made

-

- Cement Kiln Our cement kiln with sturdy structure runs smoothly and produces high quality cement clinker. It can be equipped with shaft preheater or five-stage cyclone preheater for option.

-

- Lime Kiln The lime rotary kiln is designed to produce active lime which is very popular in steel making and many other industries, such as alumina, magnesium, calcium carbide, papermaking, etc.

-

- Rotary Kiln for Nickel Laterite Ores

Application: nickel laterite ores roasting with capacity of 1950~2200t/d

Spec.: Φ5.2×118m (Inner diameter*length)

-

- Rotary Kiln for Metallurgy The rotary kiln is designed high reliability and extended working life due to shell with reasonable deflection, refractory bricks and cast refractory concrete ...

-

- Rotary Kiln for Waste Materials This rotary kiln is used in the disposal of solid waste, hazardous waste and sludge. The cement kiln co-processes with rotary kiln for waste.

-

- Rotary Kiln for Anthracite Production This rotary kiln is designed for anthracite production and clean utilization of coals. Through techniques of drying, refining, cooling and recycling...

-

- Rotary Kiln for Titanium Dioxide Production

Rotary kiln size (m): Φ2.4×38

Model: T929

Rotary speed of kiln (r/min): 0.2 ~0.6

Slope of the kiln shell (%): 2.2

Production capacity (t/d): 30

-

- Rotary Kiln for Spodumene Production (600Ton Per Day) Pengfei has realized the successful applications of rotary kiln in spodumene production projects, achieving a production capacity of 600t/d.

-

- Cooling and Drying Equipment It enables the clinker, the temperature of which is 1000℃ to 1200℃, coming from the rotary kiln to fully exchange with the air through the rotation of the shell body, making the material cool ...