- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Production Line EPC/EP

- Cement Production Line

- 3000 Ton Dry Process Cement Plant

3000 Ton Dry Process Cement Plant

Production Flow

- Limestone crushing

- Our 3000t/d dry process cement plant is available with a hammer crusher for limestone crushing, and uses a belt conveyor to deliver crushed limestone to the pre-homogenization stockyard. The stockyard is fitted with cantilever stacker and reclaimer to pile and recover limestone materials.

- The reclaimed limestone is conveyed to the limestone silo in raw material batching station, by a belt conveyer. This conveyor is designed with a metal detector at its front end to detect whether there are metal parts, and an electromagnetic iron remover so as to remove the possible metal parts in limestone. This design effectively avoids damages to raw material mills.

- Our 3000 ton dry process cement plant requires four silos in the raw material batching station for storage of ire ore tailings, limestone, silica, and wet fly ash, respectively. Each silo is designed with a plate feeder, and a constant weight feeder. Thus, the four kinds of material are discharged according to desired proportion from the silos, and then are delivered by belt conveyor to a small storehouse to be fed into raw material mill.

- Raw material grinding

- Our dry process cement plant adopts a rolling machine for raw material grinding. The machine dries materials by making use of the high temperature gas from the kiln tail, which reduces energy consumption effectively.

- The ground material is dried and classified by a V type powder separator. The fine powder material will be further processed by a high efficient powder separator. After that, the qualified fine material is delivered to the raw mix homogenization silo by the air slide conveyor and bucket elevator. While the unqualified coarse material and wet fly ash are sent back to raw material mill for further grinding and drying, until all materials are qualified.

- After passing through the powder separator, the waste gas generated during the grinding process is processed by an electrostatic precipitator before being discharged.

- Coal grinding, waste gas treatment, and raw mix homogenization

- This range of dry process cement plant includes a coal mill installed at the tail end of kiln. Part of the waste gas from the kiln is filtered by a cyclone dust collector, so as to be used as the heat source for raw coal drying. The other part is humidified and cooled down by the humidifier tower, and then enters into an electrostatic precipitator to be filtered. Finally, the waste gas is discharged into air with the help of a draught fan. The water spray amount of humidifier tower is automatically adjusted according to the outlet air temperature, so as to avoid damage to the electrostatic precipitator caused by overheat.

-

After homogenization by intensive air pressure alternatively, the raw mix in the Ф18m homogenization silo is unloaded to the mixing room via the annular zone surrounding the silo. By air-agitation method, the raw mix is mixed uniformly in the room. The air stream required for raw material mixing is provided by Roots blowers.

-

Uniformly mixed raw materials are measured, then conveyed by the air slide conveyor and bucket elevator, and finally fed separately into two preheater systems with the help of a material-distribution valve and an air-blockage valve.

- Cement clinker calcining

- The clinker calcining system of our dry process cement plant offers daily production capacity of 3000 tons, and is mainly composed of a decomposition furnace, rotary kiln, grate cooler, and dual five-stage preheaters.

- After preheating and decomposing, the feeding raw mix is fed into the rotary kiln for calcining, and then cooled in the grate cooler. Produced clinker includes both large sized lumps and small sized granules. The lumps are crushed, and then mixed with the granules. Finally, the clinker is delivered by bucket chain elevators into cement clinker silo for storage.

- The hot air generated during the previous processes are utilized as the high temperature secondary air and tertiary air for the rotary kiln and the decomposition furnace, and the waste gas are finally discharged into air after treatment by an electrostatic precipitator.

- With material discharging unit at the bottom, the clinker silo will unload cement clinker and use belt conveyor to transfer the discharged material to a bulk material stockyard. The bulk clinker can be loaded into trucks directly via the bulk material discharging hole at the bottom of the stockyard.

- Coal pulverization

- The dry process cement plant is designed with a vertical grinding mill for coal pulverization. The coal mill uses the high temperature gas from the kiln tail for coal drying. Via the weigh feeder at the bottom of raw coal silo, the raw coal is fed in desired amount into the coal mill for drying and grinding.

- Pulverized coal goes along with the air flow into the bag type dust collector. Qualified coal powder is collected, and delivered by screw conveyor into the pulverized coal silo incorporating a load sensor. After measuring, the pulverized coal is sent into the kiln burner and decomposition furnace separately, to be used as fuel. The dust-bearing gas is filtered by the electrostatic precipitator before discharging into air.

- In order to ensure safety, the dry process cement plant incorporates a CO detector and an explosion-proof valve for both pulverized coal silo and bag type dust collector. The 3000 ton dry process cement production line additionally includes a central test cabinet responsible for inspection of the fuel, semi-finished products, and finished products. Also available is an air compressor plant to generate compressed air that is necessary during production.

Equipment List

| Purpose / Descriptions | Equipment name | Type / Specifications | Quantity (set) | Annual utilization rate % |

| For limestone crushing | Single stage hammer crusher | Type: PCF2022 Max. feeding material size: 1000×1000×1500 mm Crushing capacity: 600t/h Discharging material size: ≤75 mm (90% or above) Rotor speed: 300r/min Power: 710kW Voltage: 10KV |

1 | 22.4 |

| Round shaped limestone stockyard for pre-homogenization | Limestone stacker | Type: YDQ.600/23 Stacking method: herringbone style Capacity: 600 t/h Belt width: 1000 mm |

1 | 22.4 |

| Limestone reclaimer | Type: YDQ.Q500/80 Capacity: 4000t/h Rail track diameter: Æ80.0m |

1 | 33.67 | |

| Auxiliary material pre-homogenization | Auxiliary material stacker | Type: CBD250/13.5Feeding material size: ≤40mm (85%) Capacity: 160t/h Rail track pitch: 4m Material unit-weight: 1.1t/m3 |

1 | 24 |

| Auxiliary material reclaimer | Type: CGQ150/19.5Feeding material size: ≤40mm (85%) Capacity: 100t/h Rail track pitch: 4m Material unit-weight: 1.1t/m3 |

1 | 38.2 | |

| Raw material grinding, and waste gas treatment | Rolling machine | Type: PFRM36.4 Production capacity: 250t/h (after abrasion) Feeding material moisture content: <6%Discharging material moisture content: <0.5%Feeding material particle size <75mm Discharging material particle size: 80μm Screen residue: 12% Power: 2500KW |

1 | 67.6 |

| Draught fan for raw material mill | Airflow: 495000m3/h Air pressure: 11000Pa Power: 2100KW |

1 | 67.6 | |

| Draught fan for preheater | Airflow: 580000m3/h Air pressure: 7500Pa Power: 1800KW |

1 | 85 | |

| Bag type dust collector | Type: LCM (G) 580-2×7 Filtering area: 10500m2 Airflow: 600000m3/h Flue-gas temperature: 260~150oC Inlet dust content: £100g/m3 Outlet dust content: £50mg/Nm3 |

1 | 85 | |

| Exhaust fan at the kiln tail | Type: YRKK500-8 Airflow: 620000m3/h Total pressure: 3500Pa Normal working temperature: 150℃ Max. working temperature: 250℃ Rotation speed: 740r/min Power: 1000kW Protection grade: IP44 Voltage: 10000V |

1 | ||

| Calcining system | Preheater and decomposition furnace | Five-stage preheater with online decomposition furnace Cyclone 1—2×Æ5.20m Cyclone 2—1×Æ7.00m Cyclone 3—1×Æ7.00m Cyclone 4—1×Æ7.30m C5—1×Æ7.30m Decomposition furnace: 5.6×Æ35m |

1 | 85 |

| Rotary kiln | Æ4.3×64mCapacity: 3000-3500t/d Inclination: 3.5% Speed: 0.399~3.99r/minInstalled power: 315kW |

1 | 85 | |

| Flow-control type grate cooler | Cooling area: 80.46m2 Feeding material temperature: 1400℃ Discharging material temperature: 65℃+ambient temperature Capacity: 3200t/d |

1 | 85 | |

| Electrostatic precipitator (kiln head) | Airflow: 390000m3/h Flue-gas temperature: 250℃ Inlet dust content: £30g/m3 Outlet dust content: £50mg/Nm3 |

1 | 85 | |

| Exhaust fan (kiln head) | Type: Y4-73No.23D Airflow: 400000m3/h Total pressure: 1600Pa Power: 280kW |

1 | 85 | |

| Sandshale crushing | Sandshale crusher | Category: Toothed roll crusher Capacity: 160 t/h Feeding material size: £800mm Discharging material size: £25mm Power: 130+90KW |

1 | 24 |

| Gypsum mixture crushing | Hammer crusher | Type: PCF1609 Capacity: 80 t/h Feeding material size: £800 mm Discharging material size: £25 mm |

1 | 16.3 |

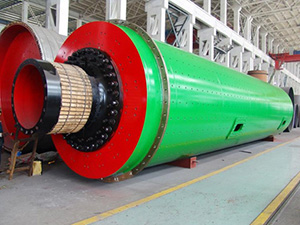

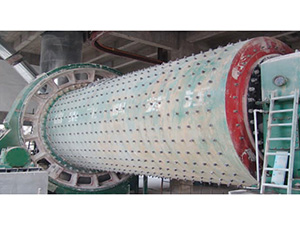

| Cement grinding | Cement mill | Size: 4.2×Æ13m Production capacity: 100~110t/h Power: 3550 KW Cement fineness: 320~350m2/kg |

2 | 58.8 |

| Cement packaging | Cement packaging machine | Type: Rotary packaging g machine with 8 filling holes Capacity: 90t/h |

2 | 26.1 |

Related Names

Cement Manufacturing Machine | Construction Machinery | Limestone Processing Technology

Send an Inquiry