- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Production Line EPC/EP

- Cement Production Line

Cement Production Line, Cement Making Machine

Pengfei Group is an EPC contractor for enterprises requiring dry process cement production lines with daily capacity no more than 10,000 tons. Its business scope covers cement production line design, construction, assembly, as well as installation and commissioning. The company also offers corresponding technical supports.

Up to now, the group has successfully built cement production lines with capacity of 600-1200t/d, 1500t/d, 2500t/d, 3000t/d, 5000t/d, and 6000t/d.

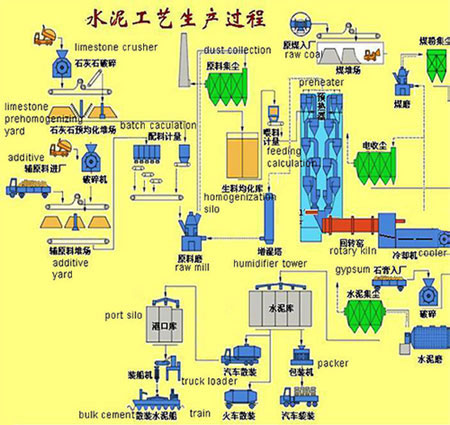

How does the dry process cement production line work?

- Material crushing and pre-homogenization

- (1) Crushing

During cement production, majority raw materials require crushing, and these materials include limestone, clay, iron ore, and coal. Among them, limestone takes the largest portion, and has relatively larger particle size and higher hardness. This makes its crushing much more important than crushing of other types of raw materials.- (2) Raw material pre-homogenization

The dry process cement production line includes a material blending bed with both material storage and material pre-homogenization functions. Thus, material pre-homogenization is realized during material storage and reclaiming process. - Raw mix preparation

- The production of every 1 ton Portland cement requires at least 3 tons of material supplies, including various raw materials, fuels, clinker, mixtures, and gypsum. Statistically, 60% of the total energy consumption utilized during dry-process cement production can be attributed to powder grinding, of which cement pulverization, raw mix grinding, and coal pulverization account for 40, 30, and 3%, respectively.

- Our dry process cement making machine ensures the fine raw material quality and minimized energy consumption, due to its optimized technological parameters and production process, high performance powder grinding mills, as well as convenient operation control.

- Raw mix homogenization

- Cement clinker is made by heating homogeneous mixture of cement-production raw materials in a cement kiln. Stabilized and uniform raw mix composition is the prerequisite of attaining stabilized clinker. Raw mix homogenization serves as the last checkpoint to realize the prerequisite.

- Pre-heating and decomposition

- Our dry process cement production line includes a preheater for pre-heating the raw mix and decomposition of some raw materials.

The preheating system carries out some of the functions of previously done by a rotary kiln, which allows for reduction of kiln length. The suspended state of raw mix in the preheater ensures maximized contact area between the materials and the heated gas exhausted from the kiln, resulting in fast heat transfer rate, and high heat transfer efficiency. Thus, the preheater also contributes to improving the production efficiency of rotary kiln, and reducing the heat consumption for clinker making.- (1) Material scattering

80% heat transfer is implemented at the inlet of the preheating pipeline. Under the impact force of the high speed upraising gas-stream in the pipeline, the feeding raw mix goes upward along with the hot air, and is scattered during the process.- (2) Gas-solid separation

When the gas-solid mixtures enter into the cyclone, they are forced to do continuous downward rotary motion in the annular space between the cyclone body and the inner air-exhaust pipe. When the mixture moves down to the bottom of the cyclone, the gas will move upward again, and finally will be exhausted from the exhaust tube.- (3) Pre-decomposition

The dry process cement production line is designed with a decomposition furnace between the preheater and the rotary kiln. Available with a fuel jetting system, the furnace makes sure the heat-generating fuel-burning process and heat-absorbing carbonate-decomposition process are conducted synchronously at a very high speed, with materials in suspended or fluidized state. This delivers high raw mix decomposition rate over 90%.

While completing the carbonate-decomposition job conventionally conducted in the rotary kiln, the decomposition furnace also undertakes the job of fuel burning, and only a small quantity of fuel is fed into the kiln head. This largely reduces the heat demand of the kiln’s burning zone, and extends the service life of kiln lining materials. This is also in favor of large cement making projects.

Additionally, the uniform mixture between fuel and raw mix ensures fast heat transfer, delivering high efficiency and low energy consumption. - Cement clinker production

- After preheating and pre-decomposition, the raw mix is delivered to the rotary kiln for calcination.

In the kiln, the carbonate is further decomposed, and also comes up a series of solid-phase reactions. The products of the chemical reaction becomes into liquid phase along with temperature increase. Some of the compositions in the molten mineral will react with each other to generate cement clinker. After that, the temperature starts decreasing.

Our dry process cement production line is available with a clinker cooling system to cool down the cement clinker delivered from the kiln, thus facilitating following steps such as conveying, temporary storage, and cement mill grinding. Meanwhile, the production line collects the sensible heat from the heat clinker, thus improving system thermal efficiency and clinker quality. - Cement grinding

- Cement grinding is the last step in cement making, and also consumes the most electricity. Our cement production line adopts a high performance cement mill to grind the cement clinker, and additives like gelatinizing agent, etc., into powder particles with desired fineness and specific surface area. After grinding, the powder comes with a specific grain composition, increased hydration speed, and increased specific surface area, satisfying the hardening demands of cement paste.

- Cement packing

- The cement can be packed by bags before leaving factory, or transported in bulk directly.

Case Studies

-

- 1000 Ton Cement Processing Line The cement production line adopts our PCD1612 single stage hammer crusher for limestone crushing. The crusher has desired capacity of 100-140t/h. It supports crushing 300mm feeding particles into 25mm ones. If working 8 hours a day, and with annual utilization rate of 30%, the crushing equipment can satisfy the 1000t/d cement production demand by offering annual crushing capacity up ...

-

- 1500 Ton Cement Processing Line

Based on dry process cement production technique, we have successfully developed this 1500 ton cement processing line. Incorporating a φ3.5×54m rotary kiln, the cement production line is designed with a decomposition furnace and a five-stage cyclone preheater at the kiln tail.

Five-stage cyclone preheating, and decomposition of powdered raw mix ...

-

- 2500 Ton Dry Process Cement Plant The 2500ton dry process cement plant adopts the MLS3626 vertical grinding mill to grind the raw mix. The mill can use the waste gas from the preheating system as the heat source for material drying. Its production capacity is 185t/h, on condition that the 90% feeding material size is no more than 75%, the discharging material size is 80μm, the screen residue of square mesh sieve is less than ...

-

- 3000 Ton Dry Process Cement Plant Our 3000 ton dry process cement plant requires four silos in the raw material batching station for storage of ire ore tailings, limestone, silica, and wet fly ash, respectively. Each silo is designed with a plate feeder, and a constant weight feeder. Thus, the four kinds of material are discharged according to desired proportion from the silos, and then are delivered by belt conveyor to a small ...

-

- 5000 Ton Dry Process Cement Plant The dry process cement production line includes a single stage hammer crusher for limestone crushing. The simplified production flow reduces electricity consumption. A vertical grinding mill is adopted for raw material grinding. As compared with conventional middle-discharging mill and air swept mill, the vertical mill reduces power consumption by 5-7kW×h/t.