- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Production Line EPC/EP

- Active lime production line

Active lime production line

PENGFEI provides active lime production line with capacity smaller than 1200 t/d.

Active lime production line configuration

| Production capacity | 300t/d | 600t/d | 800t/d | 1000t/d | 1200t/d | 1500t/d | |

| Preheater | Type | Low wear vertical warehouse compartment | Low wear vertical warehouse compartment | Low wear vertical warehouse compartment | Low wear vertical warehouse compartment | Low wear vertical warehouse compartment | Low wear vertical warehouse compartment |

| Shape | Type 6 edges | Type 12 edges | Type 12 edges | Type 18 edges | Type 20 edges | Type 22 edges | |

| Preheating warehouse number | 6 | 12 | 12 | 18 | 20 | 22 | |

| Hydraulic push rod number | 6 | 12 | 12 | 18 | 20 | 22 | |

| Preheating amount(t) | 1200 | 1200 | 1600 | 2000 | 2400 | 3000 | |

| Rotary kiln | Specification | Φ3.2×50m | Φ4×60m | Φ4.8×56m | Φ5.0×58m | Φ5.2×64m | Φ5.6×76m |

| Slope | 3.5% | 3.5% | 3.5% | 3.5% | 3.5% | 3.5% | |

| Rotary speed(r/min) | 0.3-1.8 | 0.3-1.8 | 0.3-1.8 | 0.3-1.8 | 0.3-1.8 | 0.3-1.8 | |

| Burning temperature(℃) | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Type | Partition upright | Partition upright | Partition upright | Partition upright | Partition upright | Partition upright |

| Temperature controlling zone number | 3 | 3 | 4 | 4 | 4 | 4 | |

| Air tower number | 2+1 | 4+1 | 4+1 | 4+1 | 4+1 | 4+1 | |

| Specification(m) | 3.6×3.6 | 4.1×4.1 | 4.7×4.7 | 5.2×5.2 | 5.4×5.4 | 5.8×5.8 | |

| Discharging temperature(℃) | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | |

| Product heat consumption(KJ/kg) | 5400 | 5400 | 5000 | 4750 | 4600 | 4500 | |

| Adaptable fuel | Coke oven gas, mixed gas, natural gas, pulverized coal, low-heat value gas | ||||||

Active lime rotary kiln specifications

| Specification | Φ2.5×40 | φ2.8x42 | Φ3x46 | Φ3.2x50 | φ3.2x54 | φ3.6x56 | φ3.8x58 | Φ4x60 | Φ4.3x58 | Φ4.3x64 | Φ4.8x68 |

| Volume(m3) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575 | 670 | 738 | 1005 |

| Burning temperature0C | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |

| Capacity(t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 |

Case Studies

-

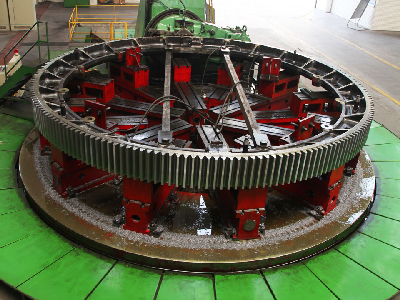

- Active lime production line (Output: 1 Thousand Tons) Pengfei provides complete equipment for an active lime production line with capacity of 1000t/d. We offer high-quality machines including lime rotary kilns, vertical preheaters and vertical coolers and reasonably designed electronic control system to meet customer’s production requirements. The production line adopts refractory materials to ensure the durability.

-

- High Voltage Cage Motor Liquid Resistance Starter Pengfei is able to offer active lime production lines with daily capacity of 600 tons. Active lime is widely used for production of steel, aluminum oxide, magnesium and calcium carbide, paper making industry and desulfurization projects in power plants. Active lime is a critical auxiliary raw material for steelmaking.

Send an Inquiry