- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Grinding Equipment

- Tube Grinding Mill

- Raw Material Mill

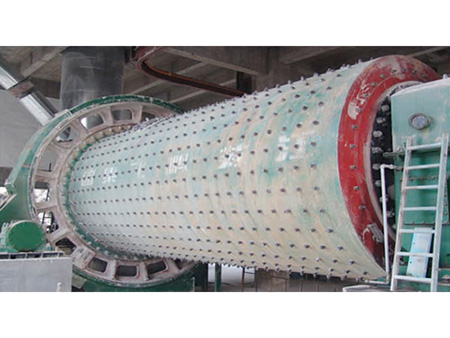

Raw Material Mill

We design this range of raw material mill for grinding the raw mix in cement production. Also applicable industries include building material, power generation, chemical, and metallurgy.

It is suitable for either dry type or wet type grinding. While supporting open circuit grinding, it can also be used with a powder separator to form a closed circuit grinding system. Additionally, it is available with drying function. Hence, the raw material mill comes in variety of versions, including dry type one, wet type one, the one with drying function, the one discharging material from the rear end, and the one discharging material from the middle part.

Designed based on the same philosophy with cement mill, the grinding equipment offers reduced ventilation resistance and increased effective volume. Hence, the material discharging is easy, and the machinery processing capacity is increased.

Both single-chamber and multiple-chamber versions are available, and different grinding chamber sections come with different types of lining plate design. Due to this design, the grinding mill delivers significantly improved processing efficiency.

| Size (m) | Rotation speed (r/min) |

Feeding size (mm) | Productivity (t/h) | Material loading capacity (t) | Main motor | Main speed reducer | Weight (t) |

|||

| Model | Power (kw) | Rotation speed (r.p.m) | Model | Speed ratio | ||||||

| φ3×(8.5+5) | 18.9 | ≤25 | 55 ~53 | 76 ~80 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 160 |

| φ3.2×(7+1.8) (with cantilever type drying chamber) |

18.25 | ≤25 | 50 ~53 | 59 | YR630-8 | 1000 | 740 | JDX800 | 6.3 | 153 |

| φ3.5×10 (with cantilever type drying chamber) |

17.3 | ≤25 | 75 ~80 | 87 | YR1250-8/430 | 1250 | 740 | JS110-A-F1 | 214 | |

| φ3.6×(7.5+1.5) | 17.3 | ≤25 | 90 ~95 | 98 | YRkk710-8 | 1400 | 740 | JDX900 | 7.1 | 220 |

| φ3.8×1.2 | 16.6 | ≤25 | 133 | 100 ~110 | YR800-8 | 2000 | 740 | JS130-A | 295 | |

| φ4.6×(9.5+3.5) | 15 | ≤25 | 185 | 175 ~180 | YRkk1000-8 | 3550 | 740 | MFY 355A | 415 | |

| Size (m) | Rotation speed (r/min) |

Feeding size (mm) | Productivity (t/h) | Material chamber capacity (t) | Main motor | Main speed reducer | Weight (t) |

|||

| Model | Power (kw) | Rotation speed (r.p.m) | Model | Speed ratio | ||||||

| φ2.4×8 | 20.91 | ≤25 | 25 ~28 | 39 ~42 | JRQ1512-8 | 570 | 740 | ZD80-9 | 5 | 76.4 |

| φ2.4×10 | 20 | ≤25 | 27 ~30 open circuit 38 ~40 closed circuit |

50 | YR710-8/1180 | 710 | 740 | JDX630 | 5.6 | 111 |

| φ2.4×11 | 21 | ≤25 | 41 ~42 open circuit 46 ~48 closed circuit |

62 ~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 125 |

| φ2.4×12 | 21 | ≤25 | 40 ~42 open circuit 45 ~48 closed circuit |

63 ~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 127 |

| φ2.4×13 | 21.5 | ≤25 | 48 ~51 | 68 ~72 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 131 |

| φ2.6×8 | 20 | ≤25 | 30 ~35 | 54 | YR630-8/1180 | 630 | 740 | JDX630 | 5.6 | 135 |

| φ2.6×10 | 20.91 | ≤25 | 45 ~46 | 80 | YR1000-8/1180 | 1000 | 740 | JDX710 | 6.3 | 136 |

| φ3×9 | 19.13 | ≤25 | 50 ~55 | 76 ~80 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 145 |

| φ3.2×7 | 18.25 | ≤25 | 50 ~52 | 58 | YR1000-8/1180 | 1000 | 740 | MBY800 | 6.3 | 140 |

| φ3.2×9 | 18.3 | ≤25 | 60 ~70 | 90 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 175 |

| φ4.6×10+3.5 | 15 | ≤25 | 195 | 190 | 3550 | 740 | JS150-B-F | 476 | ||

| Size (m) | Rotation speed (r/min) |

Feeding size (mm) | Productivity (t/h) | Material chamber capacity (t) | Main motor | Main speed reducer | Weight (t) |

|||

| Model | Power (kw) | Rotation speed (r.p.m) | Model | Speed ratio | ||||||

| φ2.2×7 | 21.4 | ≤3 | 20 ~25 | 31 | YR148-8 | 380 | 740 | ZD70-9 | 5 | 49 |

| φ2.2×13 | 21.6 | ≤25 | 33 ~37 | 58 ~60 | YR630-8/1180 | 630 | 740 | MBY630 | 5.6 | 53.4 |

| φ2.4×13 | 21 | ≤25 | 45 ~50 | 65 ~70 | YR800-8/1180 | 800 | 740 | JDX710 | 5.6 | 131 |

| φ2.6×13 | 20 | ≤25 | 45 ~46 | 80t(max) | YR1000-8/1180 | 1000 | 740 | TDX800 | 6.3 | 153 |

| φ6.2×6.4 | 18.5 | ≤25 | 32 ~41 | 86 ~90.5 | TDMK1000-36 | 1000 | 740 | 134 | ||

Note: Above technical specifications are provided for your reference only. Specific ones will be provided in purchasing contracts.

Related Names

Cement Raw Mill | Powder Grinder | Pulverizing Mill