- Jiangsu Pengfei Group Co., Ltd.

- Add.: Benjiaji, Northern Suburb of Hai'an City, Nantong City, Jiangsu Province, China

- Contact Person: Lemon Zhang

- Home

- Products

- Grinding Equipment

- Tube Grinding Mill

- Slag Grinding Mill

Slag Grinding Mill

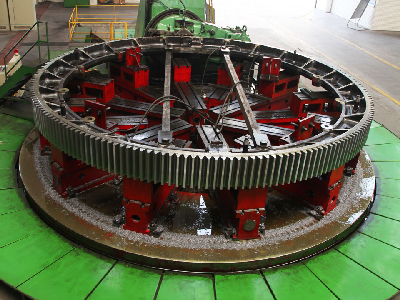

As its name indicates, the slag grinding mill is used for grinding granulated blast-furnace slag. It also suits for cement raw mix and clinker grinding. It is a key piece of equipment used after slag crushing. The grinder is often found in superfine slag powder production industry and grinding equipments. Based on our years of experience in design and production, we can offer slag grinding equipment with different specifications to deliver powder material with varied fineness.

Our slag grinding mill is built with movable lining plate, rear-end material discharging system, and a special double-partition board material chamber. The drum body interior adopts different type lining plates for different sections. Miniature grinding medium is utilized to realize material grinding in high linearity. These together ensure high production capacity, improved equipment stability, and substantially reduced electricity consumption. The grinder is also easy for installation and maintenance.

When the mill drum is driven to rotate, the grinding media will attach on the lining plate of interior drum wall to rotate synchronously, due to the action of inertial centrifugal force. While reaching a certain height, they will fall down due to the action of gravity. The falling grinding media crush the materials in the drum because of impact force. Meanwhile, the grinding media will repeat its synchronous rotation and falling down movements continuously. During the process, they will cause rolling and sliding movements as well, resulting in abrasion among the grinding media, lining plate, and slag materials. Thus, the materials are ground into finer ones.

| Product size (m) | Productivity (t/h) | Drum rotation speed (r/min) | Drive type | Power (kW) | Main speed reducer | Weight (t) | Remark | |

| Model | Speed ratio | |||||||

| φ2.2×6.5 | 18 | 21.4 | Edge-drive | 310 | ZD70 | 5 | 44 | |

| φ2.4×8 | 26-28 | 20.14 | Edge-drive | 570 | ZD80 | 6.3 | 90 | |

| φ2.6×13 | 11-15 | 19.7 | Edge-drive | 1000 | JDX800 | 6.3 | 137 | High fineness slag grinding mill |

| φ2.8×6.5 | 35 | 18.65 | Edge-drive | 630 | ZD80 | 6.3 | 100 | |

| φ2.8×10 | 45-48 | 18.65 | Central drive | 800 | MFY80 | 37.5 | 160 | |

| φ3×6.5 | 37 | 18.58 | Edge-drive | 800 | JD800 | 5.6 | 115 | |

| φ3×9 | 40-50 | 18.58 | Edge-drive | 1000 | JD800B | 5.6 | 132 | |

| φ3×12 | 65-75 | 18 | Central drive | 1400 | JS110-B-F1 | 42.22 | 202 | Wet type |

| φ3.2×13 | 72-75 | 17.86 | Edge drive | 1400 | JDX900 | 6.3 | 237 | Wet type |

| φ3.4×7.5 | 70 | 16.9 | Edge-drive | 1000 | ZDA-100 | 6.3 | 167 | |

| φ3.5×10 | 90 | 16.8 | Central drive | 1250 | Js110-A | 44.1 | 154 | Drying function, middle-discharging type |

| φ4.6× (7.5+3.5 ) | 180 | 15 | Central drive | 2500 | --- | -- | 272 | |

| φ4.6× (10.5+3.5 ) | 210 | --- | Central drive | 3550 | JQS3550 | 15.1 | 360 | |

Note: Above technical specifications are provided for your reference only. Specific ones will be provided in purchasing contracts.

Related Names

Blast Furnace Slag Grinder | Slag Ball Mill | Slag Processing Plant